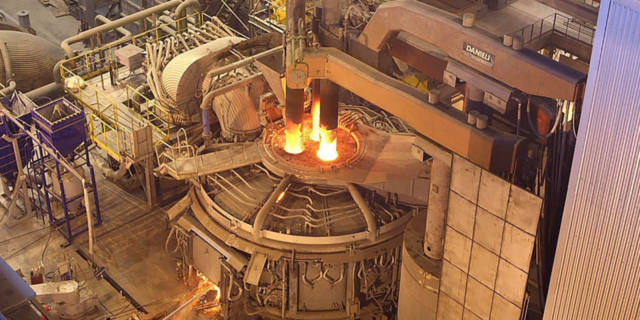

Electric arc furnaces are widely used in the steel industry for melting, refining, and alloying steel. To power the electric arc, graphite electrodes are used. In this blog post, we will look at what electric arc furnaces and graphite electrodes are, the reasons for using them, their advantages, and how to select the right graphite electrode for your application.

What Is An Electric Arc Furnace?

Are you looking for a way to produce high-quality metals at a lower cost? If so, you may be interested in electric arc furnaces. These furnaces use graphite electrodes to provide energy for the furnace, and as a result, they have many advantages over traditional materials.

For example, graphite electrodes can generate higher temperatures than traditional materials. This means that they are better suited for melting and remelting metals – such as steel – into new products.

Another advantage is their larger surface area. This means that they can generate more sparks than other types of electrodes, which reduces pollution and makes the furnace safer.

Additionally, because they are durable and cost effective, electric arc furnaces are perfect for applications where high-quality metals are needed quickly, such as in steel manufacturing processes.

In addition to metal processing, electric arc furnaces can also be used to melt and remelt a variety of other substances. They are especially popular in the production of stainless steel due to their ability to increase efficiency while reducing energy consumption.

Graphite rods also have a number of unique properties that make them useful in a variety of industrial and commercial applications. They are known for their high thermal conductivity, chemical resistance, electrical conductivity, and mechanical strength. Due to these properties, graphite rods are used in a wide range of applications, including as electrodes in electric arc furnaces, as anodes and cathodes in electrochemical processes, as moderators and structural components in nuclear reactors, and as components in high-temperature heat exchangers. Graphite rods are also used in mechanical applications that require high strength and low friction, such as bearings and seals.

With so many benefits to electric arc furnaces, it’s no wonder that this type of furnace is becoming increasingly popular in the industry.

How Graphite Electrodes Revolutionize Metal Production?

Industry experts agree that the future of metal production lies with graphite electrodes. Here are just a few of the reasons why they are so powerful:

First, graphite electrodes enable more efficient and cost effective metal production. Traditional ones require a lot of energy to create an arc, which can lead to high emissions and costs. With graphite electrodes, however, you can still produce high-quality metals using less energy. This is because the design of these electrodes helps reduce slag foaming in the furnace – meaning that more metal is remelted at once with less waste.

Second, they provide a consistent, concentrated arc during electric arc furnace remelting – which means that products are produced consistently and with minimal variation. This is important because it means that you don’t have to waste time and resources refiring an electrode multiple times in order to get consistent results. In addition, this technology allows for longer melt times and improved product quality – meaning that you’re getting more value for your money.

Next, they help to reduce emissions by controlling temperature distribution throughout the furnace – which leads to less heat being lost through the roof or walls of the furnace. This can save energy both overall and per unit of product produced.

Also, their longevity is impressive – they last up to twice as long as traditional electroding materials without deteriorating or requiring replacement often. As a result, you can save money on replacement costs over time while still achieving high-quality products!

– Finally, by using this technology in your metal production process you can improve both production efficiency and environmental impact simultaneously. By reducing energy consumption (and emissions), you’re helping to mitigate climate change while increasing productivity in your factory.

Reasons For Using Graphite Electrodes In Electric Arc Furnaces

When it comes to electric arc furnaces, graphite electrodes are the gold standard.

1. They have a higher melting temperature and better electrical conductivity than other types of conductor material, which makes them ideal for heating up metal to high temperatures.

2. Additionally, they enhance the performance of electric arc furnaces by providing higher heat conduction, faster arc disruption, and lower electrode wear. This means that they produce more heat and melt more metal than other types of electrode material.

3. They also have a longer life cycle than other types of electrode material, which means that they can be used multiple times without losing their performance.

4. In addition to being more cost effective than other materials, they require less maintenance – making them a preferred choice for industrial applications where robust performance is required without constant upkeep.

5. Finally, they produce fewer emissions than other metals, resulting in improved environmental pollution control.

How To Select The Right Graphite Electrode For Your Application?

When selecting the right graphite electrode for your application, it is important to consider the size, shape, chemistry, and physical properties that address your needs. Additionally, it is important to buy the best graphite electrodes with vibration protection features for optimal performance. When selecting an electrode, it is also important to consider its design and whether it will fit into your existing system. Look for electrodes that have been machined and polished to ensure a consistent surface finish. Finally, ensure that they are made from high quality graphite materials and are built to last. Consider cost, availability, and delivery time when selecting the right graphite electrode for your application.

In conclusion, graphite electrodes are an essential component of electric arc furnaces and offer many advantages over traditional electrode materials. They enable more efficient and cost-effective metal production, provide a consistent and concentrated arc during electric arc furnace remelting, reduce emissions by controlling temperature distribution throughout the furnace, last up to twice as long as traditional materials without deteriorating or requiring frequent replacement, and improve both production efficiency and environmental impact simultaneously. If you are looking for an efficient way to produce high-quality metals while reducing energy consumption and emissions at the same time, then graphite electrodes are definitely worth considering.