Owning a business that relies heavily on having a warehouse full of inventory and enough of it to meet the demands of customers is challenging for numerous reasons. Such work needs a different approach from regular business that do not have the need for extensive storage and lots of space to move around and keep the important goods they deal with on a daily basis.

If you are among the owners who need proper storage organizing, you know full well how dependent the success of your operations and the revenue that comes in each year are on the right type of plan and system.

In case you are experiencing issues with this, you are in luck because this article will act as a guide and give you all the tips you need to choose the best type of warehouse racking system your business needs.

Once you know what to aim for, what to consider, and how to properly evaluate if something is needed or not, there will be no more money, time, and brainwork wasted on finding the right way around it. If you are further interested in the matter, we advise you to check out Camrack.

The needs of your storage or the amount of things you have to have at any given time will directly influence what type of racking system you may need. Some systems are better for certain branches of industry while others are not. The ideal choice for you will become clear only when you know the practices, needs, and daily routines of your operation.

Selective, drive-in, double-deep, pallet flow (live racking), push back, and narrow isle are all viable options but they are used in different industries and for vastly different products that do not have the same shelf life. Think about what kind of goods you are dealing with and how often they have to be moved or stored. Only then can you know more.

2. Expand Vertically

Expanding your storage vertically instead horizontally in any given direction is more convenient but only if you have sturdy shelves of high quality. You cannot do it infinitely either because sooner or later you will reach the ceiling. In any case, to maximize the storage potential of your warehouse and get the most out of the new system you want to adopt, you should always expand up instead of straight or to the sides.

Renting bigger warehouses or expanding your own are both more expensive options that maximizing the existing space to meet the demands of your growing business. Remember that it is a good thing that all of a sudden you require more room. It means you are expanding. Look for the pallet tacking systems that favors high shelves and adding more rack levels. Look for a facility that has systems that use vertical assist technology, comparable to Modula storage.

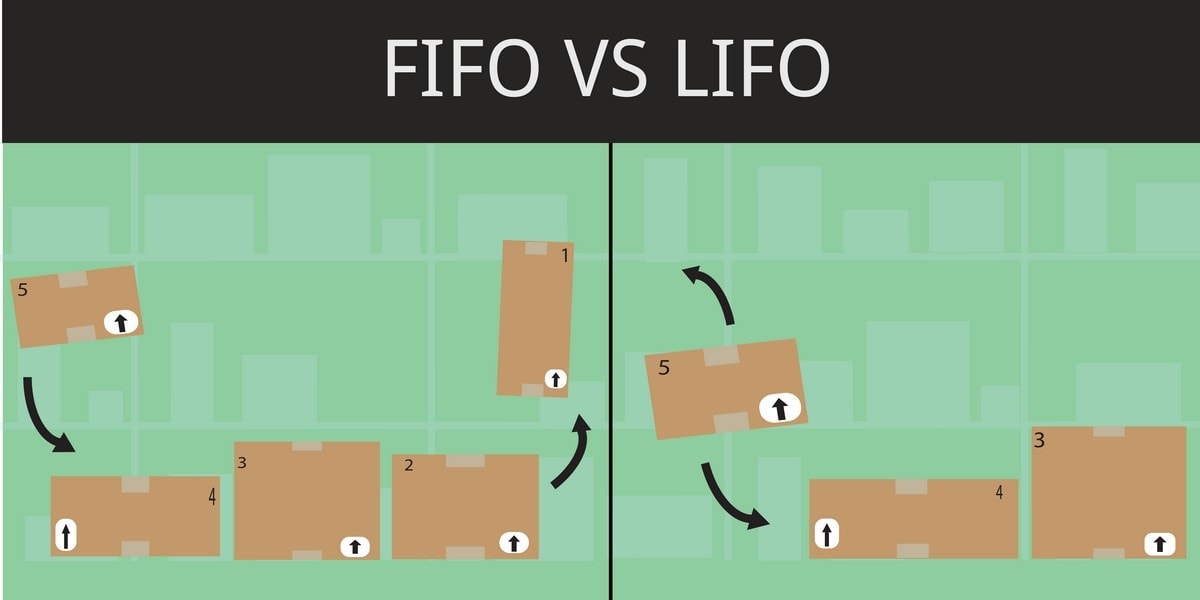

3. FIFO or LIFO

FIFO stands for “first in, first out” and LIFO means “last in, first out” and these two systems are crucial for the type of racking system your warehouse and business needs. The flow of pallets is completely different if the thing that was loaded in first has to come out rarely, and if the delivery that came in last goes back out soon.

Deep-lane storage is the best choice for LIFO, while pallet flow racks are the best for FIFO. If you fail to recognize the kind of rack system you have based on these two approaches, you may risk having a lot of buried loads that are near-impossible to reach. This directly leads to downtime, disrupted flow of operations, and less revenue in the end.

4. Forklift Usage

Again, based on the type of goods you are using and how heavy they are, you may require different types of forklifts. You may only need a small pallet forklift or a full-on, drivable forklift truck. It all depends on the height you need to reach, the volume of packages and loads coming in and going out, and how many employees you have.

If you require true forklifts, there also has to be enough room between the shelves for them to operate and move freely. However, you can also go more up since they are able to pick up boxes that are much higher. On the other hand, in case you do not need vehicle-type forklifts for your warehouse operations, the workers may do it manually and the racks can be tighter together, with more racks inside the warehouse.

5. Selectivity Matters

If a business has a 100% selectivity rate, it means that literally any type of product they have in stock may be needed at any time. This further means that all of the warehouse has to be accessible at all times because an order may come in for any of the things the storage houses. Deep-line storage is definitely not the option here then. You will require a system that allows you to reach any rack in an optimal amount of time.

The organization has to be well-thought out and follow a certain pattern that makes sense like alphabetically or according to the product or part type. If you have certain items that are more commonly moved by far when compared to the rest, they should be much more easily accessible in comparison to the things that almost never leave the premise.

6. Type of Warehouse

Last but not least, we have to mention the kind of warehouse your business has. Not all warehouses are the same as some of them act as just warehouses where the company store the products they sell and use. The others have double or even triple functions and act as warehouses only partially.

For example, a company can have some kind of a service shop or mechanical operations going on in the warehouse. If only a part of the whole building is sued for storage, you have to think about how it may disrupt or enhance the flow of other things that are going on in there. Think about the different employees who do different things and make sure the system you pick does not limit their ability to roam around the warehouse.