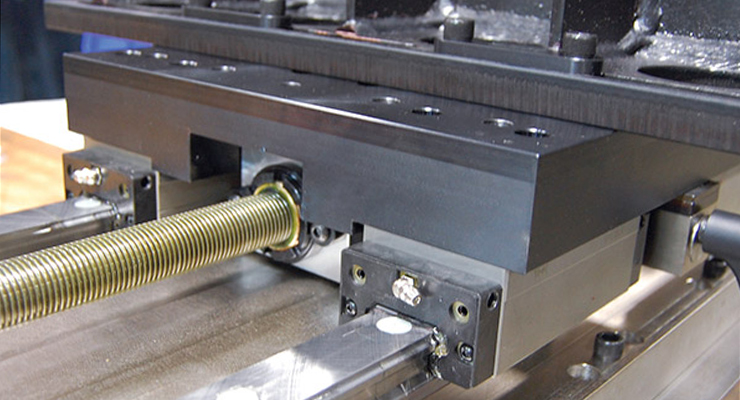

Linear motion pieces are metal elements that are often used to build different types of machines. Linear guides are the best choice for implementing automation requirements, since most of them can move in all directions, and they are suitable for almost every type of systems and machines. As you can see on tuli-shop.com, they come in different shapes, and every one of them has a different purpose in machine engineering, and building up a complete industry system.

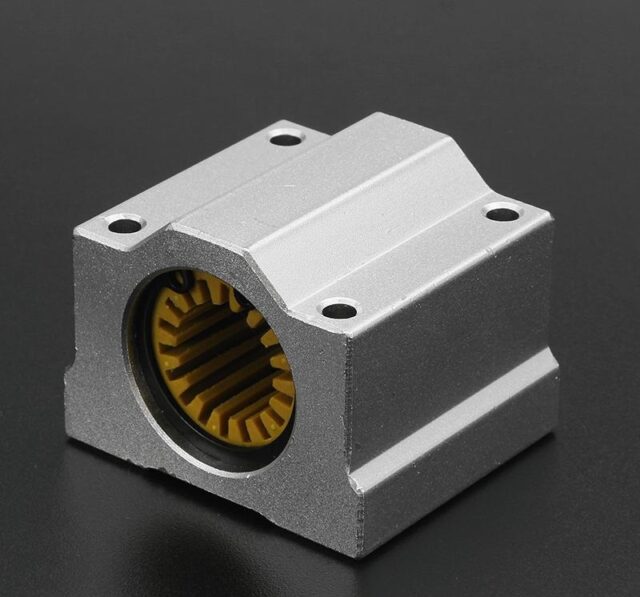

But, we all know the struggle of friction between two surfaces may cause some problems. According to physics, every surface, no matter how smooth it looks, when touching, sliding, or rotating near another surface, may cause reduced efficiency, and even damage to the crucial parts of the machines, so the engineers were looking for a solution to this problem, that will reduce the friction, and improve the working cycle of the machines. So, if we need to define what is bushing, we can say that it’s a tube around some part of the machine, that easily slides, it’s made of quality material that stops the friction, and helps the parts slide against each other, without causing any damage. It often has a cylindrical shape, with both of the ends open, so the sliding can be easy.

Some materials are self-lubricating, and some of them should be helped with some oil or oil-free lubrication, depending on the type, so they can work well. Most of the engineers consider slide bushing more efficient than the ball bearing, and at the same time, it’s cheaper and more effective and doesn’t cause loud noise and vibrations.

When the friction is low, the machine doesn’t spend much energy to work. The linear slide bushing is also known as oil-free bushing because in most cases, it doesn’t need additional substances to do its job perfectly. Again, according to physics, if the friction coefficient between two surfaces is high, it may lead to damages that can stop the machine from working or require additional power to complete the task. So, if you are sure that you want to replace the current systems with a slide bushing technology, then you should:

1. Simplify the whole process

New machines use new technology that is cost-efficient and energy-efficient too. Consider replacing the ball mechanisms with cylindrical ones, so you can improve the overall performance. If you are a part of the transportation industry, food processing, or electronic elements producing, then you can talk with your engineer about how to make the machines more efficient, by simply replacing some parts of them. New generation technologies are developed to save money and energy, and that’s what you exactly need for your company, in order to be completely efficient all the time.

2. Learn how it works

You don’t have to be an engineer to understand how these simple things work. Understanding the slide bushing in linear motion machines is simple – it’s an additional part of the mechanism that helps the whole line not to consume a lot of energy, and to avoid self-heating as a result of the friction between two surfaces. This is one of the first lessons we are learning at school, in history classes, when they teach us that the early humans were using the friction between two stones or pieces of wood to set a fire. And now, when we live in modern times, we don’t want to set fire over the whole factory, and the slide bushing and other similar technologies, including the ball bearing, can prevent that to happen.

3. It’s all about the smooth motion

When the small parts of the machine are working smoothly, then the whole line will work well, without stops and huge problems. The small alerts are always easier to solve, and we can prevent a lot of bad things to happen using these small elements. Most of the time they are designed together with the machine, and you don’t have to add them manually. But, if you own an old type of machine, then you may consider a few improvements, especially if you see that the current line consumes a lot of energy and money for regular maintenance.

4. Choose an appropriate material

Choosing the material is the main way to prevent friction. Learn the physics behind the materials, or even consult with your engineer, so you can find the best possible solution. Since the parts of the machines are often made of metals, you can choose some material that won’t break under the pressure and will let the whole system work without stopping.

5. Let the professionals do their job

Not every person is eligible to open the machine and install the new parts in them. But, when you hire professionals to do that, or you have a competent worker in your company, then you can be sure they will use the proper method to install the slide bushing elements, without damaging the other parts of the system. The good thing is that it doesn’t require much time for the process to be completed, so you won’t have to stop or postpone the working cycle for long.

6. Don’t go for the first offer you get

You have to collect a few offers, so you can compare the prices and see what they really have to give. Sometimes we don’t want to lose time on things like this, but the truth is we can save a lot of money if we are more careful when choosing these things. A cheap offer doesn’t mean a good offer. So, don’t choose these things alone, and always have your engineer near you, so your team can decide what is best for the company’s improvement.

And remember, sliding is always a better choice over anything else because the whole process is smooth and doesn’t cause friction and other unpleasant things for the machines. Consider this as a nice solution for your industry line, and use these tips to find the best offer for you.