Ball spline shafts are a type of linear motion system designed to counter the limitations of traditional splines, providing smoother motion and reduced friction. The SC 6 TBI Motion, a smaller variant, boasts remarkable precision, making it ideal for applications where space is limited and exacting performance is necessary.

On the other end of the spectrum, the SC 50 TBI Motion is a robust, heavy-duty solution capable of handling substantial loads and enduring challenging environments.

These components are playing a crucial role in many industries since they are providing the right performances for linear motion. Also, keep in mind that there are many producers available. However, not all of them can provide the right quality.

In that matter, you should visit the Tuli store, and choose from a wide range of products like ball spline shafts, linear motion products, or aluminium profiles like https://www.tuli-shop.com/alu-profile-systems/aluminium-profiles

The key role of these components is improved precision and control. These features are crucial for linear motion guides. In this article, we will provide more details about the main features of different ball splines shafts.

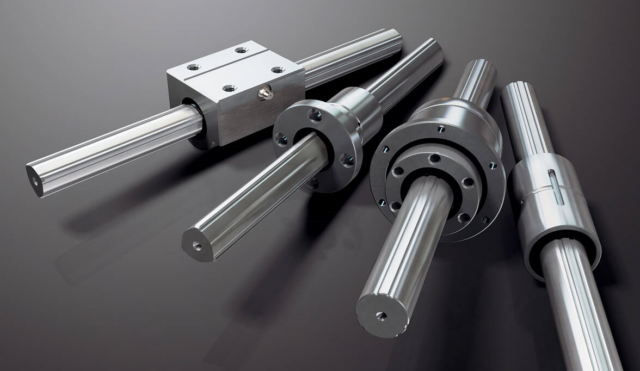

Most Common Types

There is a wide range of products that can be used in linear guides. Besides the TBI, there are also THK, SFJ, Bosch Rexroth, NB, and Schneeberger. All of them are used in various processes like heavy-duty machinery, the production of electronic equipment, industrial machinery, automation, aerospace, precision control, and more.

When it comes to the SC series, the range goes from SC6, over SC8, 10, 25, and SC50. The most important feature is the high accuracy that is provided to the system, making these shafts necessary in the production of semiconductors, medical equipment, and more.

Main Features of TBI Motion

SC 6, on the other hand, is ideal for smaller manufacturing lines. High precision, smooth motion, minimal friction, and adaptability are some of the key qualities. Because it can offer linear motion with minimum backlash, this component is ideal for rapidly manufacturing tiny components.

The ability to tolerate pressure and offer precision are the primary reasons it is widely used in robotics and medical equipment manufacture. The revolutionary design prevents friction and produces outstanding results in terms of longevity and efficiency.

When it comes to the SC50, it is ideal for tough construction and demanding environments. The main attribute is the capacity to manage large load activities with improved steadiness.

There are many other types available in the same category. For example, the SC 8. This model is made for medium-duty performance and moderate loads. The main advantage is that it can handle higher speeds and loads while still being able to reduce the noise.

Therefore, it is perfect for rapid automation systems. Therefore, it is unsurprising that this model is most common in packaging lines.

The ability to handle higher speeds without noise is also one of the main characteristics of the SC 16. This model is common on 3D printers and CNC machines, and many medical devices use it.

Another model that we have to mention is SC 25. It is designed to carry heavy loads while handling pressure without much noise. The common use is in construction equipment and material handling.

Important Role in Different Industries

The key role of different models of ball spline shafts is to provide accurate linear motion and control. They are designed to follow specific requirements of tools and machines related to different industries.

For instance, it will provide a safe and reliable process by reducing friction and providing smooth movement.

Also, they will reduce or remove the backlash when the components are changing directions. This is a crucial feature since it provides higher stability. Without it, certain components could easily break down.

Different models within the SC series offer varying load-bearing capacities. They can handle different levels of loads, from light to heavy-duty, making them suitable for a wide range of industrial equipment and machinery.

Some SC TBI Motion ball spline shafts, like the SC 6 and SC 16, are designed with a smaller form factor, making them ideal for applications with limited space constraints.

They offer versatility, finding utility in robotics, automation, aerospace, semiconductor manufacturing, and medical devices. On the other hand, ball spline shafts like the SC 50 and SC 25 are built to handle substantial loads and challenging operating conditions, making them suitable for heavy machinery, construction equipment, and industrial automation.

The SC series boasts high precision in transmitting linear motion, ensuring minimal deflection and stability during heavy load operations. This precision and rigidity are critical for applications demanding accurate positioning and repeatability.

Certain models are designed with noise reduction features, ensuring smooth and silent linear motion, essential in noise-sensitive applications.

How Does It Work?

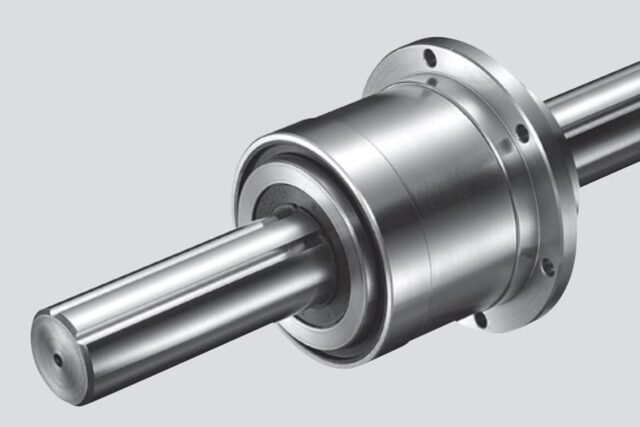

The operation involves the interaction of several key components. The primary goal is precise linear motion. The ball bearings are at the core of the operation. These small, precision-engineered elements are placed between the inner and outer races.

They are what enable smooth motion and reduce friction during operation. The spline shaft is the inner part of the ball spline, while the bushing is the outer component. The spline shaft contains grooves or splines that the ball bearings move along.

The bushing surrounds the spline shaft and holds the ball bearings in position. When a force is applied to the spline shaft, it moves linearly within the bushing.

The ball bearings, situated between the grooves of the spline shaft and the bushing, facilitate this linear motion. As the spline shaft moves, it causes the ball bearings to roll along the grooves, guiding the linear movement.

The Bottom Line

As you can see, there are different types of these components. If you are planning to start production, it is essential to choose the right one since it will provide the right condition to the whole line.

The best part is that there is a wide range of sizes and other special features that can be implemented in different industries.