If you’re looking for a framing solution that is both strong and durable, you may be considering welded steel frames.

However, aluminum extrusion frames offer several advantages over welded steel frames, making them a better choice in many applications. The benefits of aluminum extrusion frames and why they are often a better option than welded steel frames.

These frames are less expensive than welded steel frames

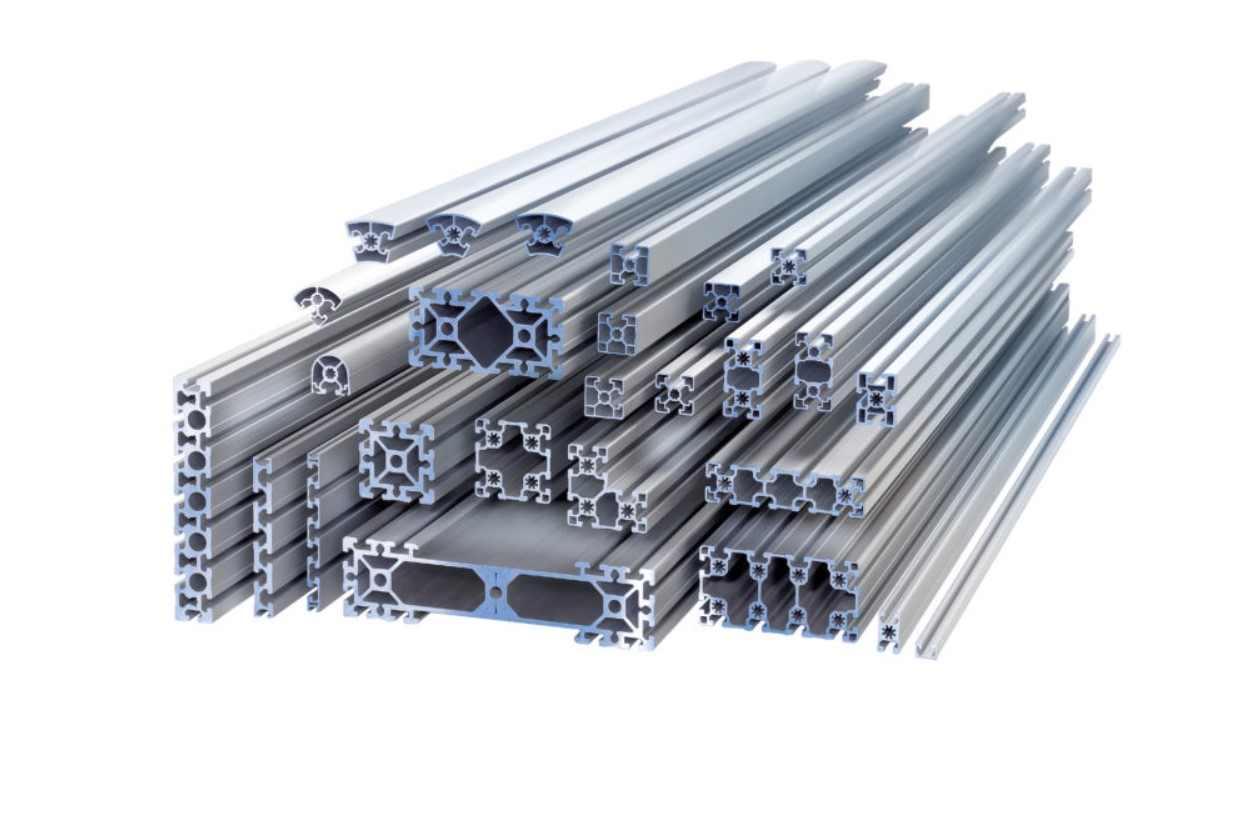

Aluminum extrusion frames have many advantages over welded steel frames:

1. They are less expensive.

2. They are lighter in weight, which creates them easy to handle and transport.

3. They are more corrosion-resistant.

4. They are easier to recycle.

5. They offer a more comprehensive range of design options.

Aluminum extrusion frames are an excellent choice for a variety of applications. They are less expensive, lighter in weight, more corrosion resistant, easier to recycle, and offer a broader range of design options. As a result, they are a great choice for a variety of applications.

They are stronger and more durable than welded steel frames

Aluminum extrusion frames have many advantages over welded steel frames. One advantage is that aluminum extrusion frames are more robust. This is because the aluminum alloy used in extrusion is much stronger than the steel used in welding. The 7075 extruded aluminum is with high strength. As a result, aluminum extrusion frames can better withstand impact and vibration forces.

Another advantage of aluminum extrusion frames is that they are more durable. This is because the aluminum alloy used in extrusion is more corrosion-resistant than the steel used in welding.

As a result, aluminum extrusion frames will not rust or corrode as easily as welded steel frames. Finally, aluminum extrusion frames are more environmentally friendly. This is because the aluminum alloy used in extrusion can be recycled after use, whereas the steel used in welding must be disposed of in landfills. As a result, aluminum extrusion frames are a more sustainable option for frame construction.

They do not rust or corrode like welded steel frames

Aluminum extrusion frames offer several advantages over welded steel frames:

1. They do not rust or corrode like welded steel frames. This means they will not break down over time, even in environments exposed to moisture or chemicals.

2. Aluminum extrusion frames are much lighter than welded steel frames, making them easier to transport and install.

3. Aluminum extrusion frames can be recycled at the end of their life cycle, whereas welded steel frames must be disposed of as waste.

As a result, aluminum extrusion frames are a more sustainable choice for construction projects. Finally, aluminum extrusion frames can be customized to meet the specific needs of a project, whereas welded steel frames are limited to standard sizes and shapes. This makes them a unique choice for applications requiring a unique design.

They are lighter than welded steel frames, making them easier to transport and install

One of the greatest considerations when choosing a framing material is weight. Lighter materials are generally easier to transport and install and place less strain on supporting structures. For this reason, aluminum extrusion frames are often preferable to welded steel frames.

Aluminum is also more resistant to corrosion than steel, making it a good choice for outdoor applications. In addition, aluminum extrusions can be produced in various shapes and sizes, giving designers greater freedom to create custom solutions. As a result, aluminum extrusion frames offer many advantages over welded steel frames.

They are lightweight and easy to install

In many applications, aluminum extrusion frames offer several advantages over welded steel frames. Aluminum is much lighter than steel, so extrusion frames are easier to handle and less likely to cause injuries during installation. In addition, extrusion frames can be quickly assembled without welding or other specialized equipment.

This makes them an important choice for applications where speed and ease of assembly are critical. Extrusion frames are also more resistant to corrosion than welded steel frames, which is an essential consideration in outdoor or coastal applications. Overall, aluminum extrusion frames offer several advantages over welded steel frames.

Low weight for easy transport

As the popularity of aluminum extrusion grows, more and more industries are turning to this versatile material for their framing needs. Unlike welded steel, which can be heavy and difficult to transport, aluminum extrusion is much lighter in weight. This makes it ideal for applications where frames must be moved frequently or transported over long distances.

In addition, aluminum extrusion is much less likely to warp or become distorted during fabrication. As a result, it can provide a more robust and more accurate finished product.

Overall, aluminum extrusion offers several advantages over welded steel, making it the preferred choice for many framing applications.

Versatility for a wide range of applications

Aluminum extrusion offers many advantages over welded steel frames, making it the ideal choice for a wide range of applications. One of the most significant benefits is its versatility. Aluminum extrusions can be easily cut, drilled, and machined to create custom shapes and sizes, which is challenging to do with welded steel frames.

As a result, aluminum extrusions can be used in various applications, from small electronics to large machinery. In addition, aluminum extrusion is significantly lighter than welded steel, making it easier to transport and install. And because it is corrosion-resistant, aluminum extrusion is an excellent choice for outdoor applications. Overall, aluminum extrusion provides a versatile and durable solution for many needs.

Conclusion:

In conclusion, there are several advantages that aluminum extrusion frames have over welded steel frames. Aluminum is a lighter-weight metal, making it easier to work with during manufacturing.

In addition, aluminum extrusions can be created in various shapes and sizes, which gives designers more flexibility when creating products. Finally, aluminum extrusion frames are not susceptible to weld decay, which can cause product failures over time. Taken together, these advantages make aluminum extrusion an attractive option for various applications.